- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Shop Press Parts

- Custom Sheet Metal Stamping(S.S. 301)

- Fly Press Parts

- Sheet Metal Components

- Press Tool Component

- Sheet Metal Pressed Components

- Stamping Automotive Parts

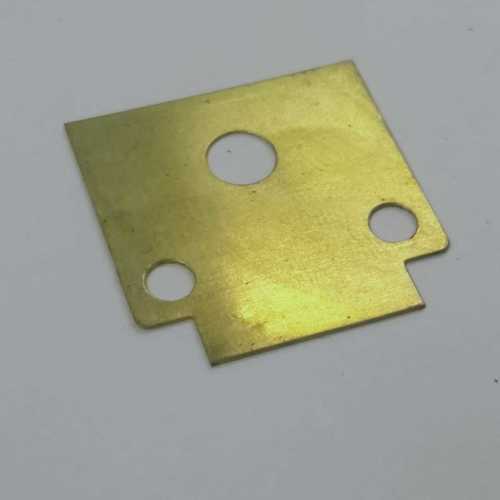

- Brass Pressed Components

- Precision Custom Sheet Metal

- Sheet Metal Dies

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Auto Electrical Sheet Metal Components

- Custom Sheet Press part

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

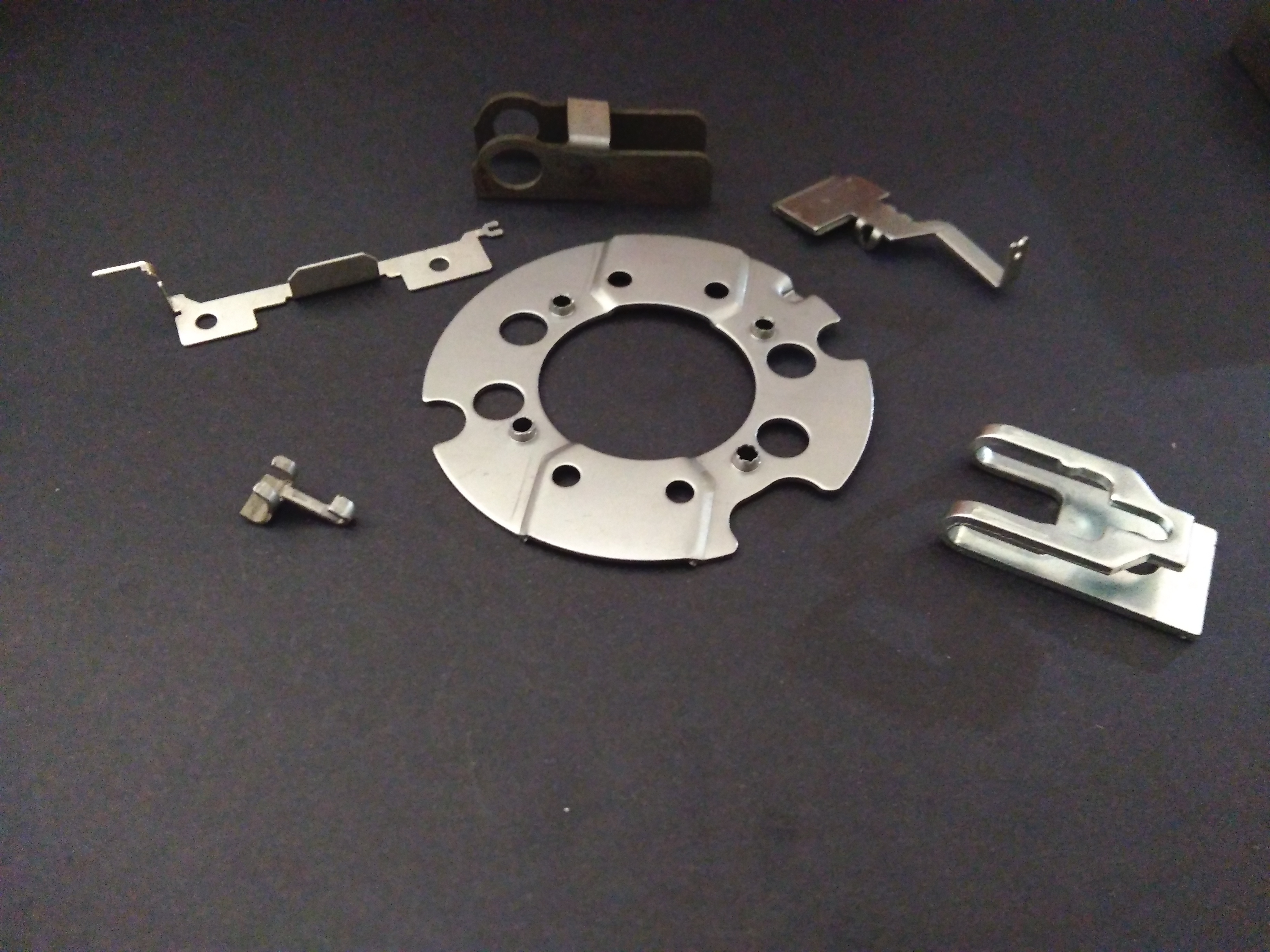

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

Punching Parts

Price 2 INR/ Piece

MOQ : 50000 Pieces

Punching Parts Specification

- Material

- Stainless Steel, Steel, Aluminum, Copper

- Surface Treatment

- Nickel Plating

- Making Process

- Stamping

Punching Parts Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10000000 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per industries standers

- Main Export Market(s)

- Central America, Western Europe, Australia, North America, Eastern Europe, Middle East, South America, Africa, Asia

- Main Domestic Market

- , Manipur, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Jammu and Kashmir, Jharkhand, Maharashtra, Mizoram, Meghalaya, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Nagaland, Gujarat, West Bengal, Madhya Pradesh, Karnataka, North India, Kerala, Central India, Odisha, Chhattisgarh, All India, Haryana, Andhra Pradesh, Uttar Pradesh

- Certifications

- ISO 9001-2015

About Punching Parts

Punching parts

We are the leading manufacturer of punching parts. We have experience in punching of various materials like phosphor bronze, copper, brass, stainless steel, c55, mild steel of thickness 0.10 mm to 3mm.

We are an ISO 9001:2015 certified company established in the year of 2005 with a vision to become one stop solution provider for all the punching requirements of our customers.

Our immense experience and in-house facilities of tool manufacturing accompanied by our modern machinery gives us competitive edge over our competitors.

We have press machines of capacity 10 ton to 45 ton of machines of speed 200 to 600 spm to cater for every requirements of our customers .Mass production with precision is our specialty.

We have facility of surface finishing and plating at our reliable and trustworthy vendors to provide ready to use finished products to our customers .We have track record of growing customer satisfaction due to our adherence to ISO 9001:2015 policies which includes total customer satisfaction.

Precision Manufacturing Process

The punching parts are formed through a stamping process, ensuring high precision and consistency across batches. Each part is manufactured using state-of-the-art machinery and then undergoes nickel plating to enhance durability and corrosion resistance. Our expert team meticulously monitors every step, providing products that adhere to strict international standards.

Versatility in Material Selection

We offer punching parts crafted from a range of premium materials including stainless steel, steel, aluminum, and copper. This versatility allows us to cater to diverse application needs, ensuring optimal performance regardless of the operational environment. The combination of robust materials and nickel plating guarantees long-lasting and dependable components.

FAQs of Punching Parts:

Q: How are punching parts with nickel plating manufactured?

A: These parts are produced through a stamping process, where sheets of stainless steel, steel, aluminum, or copper are shaped using a die. After stamping, the parts undergo nickel plating, which deposits a uniform layer of nickel to enhance surface hardness and resistance to corrosion.Q: What materials are available for your punching parts?

A: We manufacture punching parts using premium materials including stainless steel, steel, aluminum, and copper, allowing us to cater to specific industry and application requirements.Q: Where are these nickel-plated punching parts commonly used?

A: Nickel-plated punching parts find applications in automotive, electronics, consumer goods, machinery, and construction industries due to their excellent durability and corrosion resistance.Q: When should I consider using nickel-plated punching parts?

A: You should opt for nickel-plated punching parts when your application requires enhanced protection against oxidation, wear, and mechanical stress, or when a polished and attractive appearance is desired.Q: What benefits does nickel plating provide for punching parts?

A: Nickel plating offers several advantages, including improved corrosion resistance, increased surface hardness, better wear protection, and an appealing finish, extending the service life of your components.Q: What is the process for ordering these parts from your company in India?

A: You can place an order by contacting us directly with your specifications. Our team will assist you with your requirements, recommend suitable materials, and provide a quotation followed by efficient manufacturing and export logistics.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free