- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Sheet Metal Pressed Components

- Brass Pressed Components

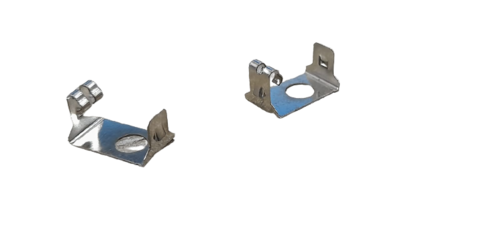

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Dies

- Sheet Metal Components

- Stamping Automotive Parts

- Shop Press Parts

- Press Tool Component

- Fly Press Parts

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Custom Sheet Press part

- Auto Electrical Sheet Metal Components

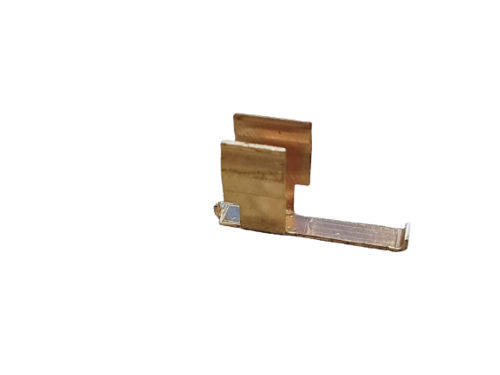

- Brass Lug

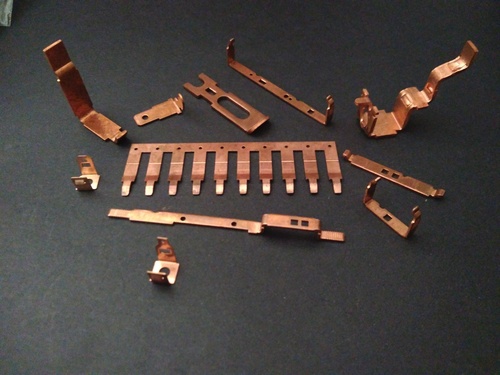

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

Progressive Sheet Metal Component

Price 0.60 INR/ Piece

MOQ : 50000 Pieces

Progressive Sheet Metal Component Specification

- Material

- Stainless Steel

- Thickness

- 1-10 Millimeter (mm)

- Capacity

- 10-50 Kg/hr

- Surface Treatment

- Polishing

- Making Process

- Mig Welding

Progressive Sheet Metal Component Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10000000 Pieces Per Month

- Delivery Time

- 1-2 Week

- Main Domestic Market

- All India

About Progressive Sheet Metal Component

Alexander Part

Extensive assortment of mechanically structured Alexander Parts are being offered by us in the national market. The manufacturing of these parts are done using the best raw materials along with up to date techniques. They are used to support various industrial applications in the most effective and efficient manner. The Alexander Parts are tried and tested on the basis of number of quality and functionality parameters to ensure their intact performing ability for an adequate time period.

Precision Engineering Through MIG Welding

Every progressive sheet metal component is fabricated using MIG welding, a process known for its accuracy and strength. Paired with stainless steel of varying thicknesses, our welding expertise guarantees consistent and durable joints, making these components suitable for demanding environments.

Superior Quality with Polished Stainless Steel

Our commitment to using high-grade stainless steel, combined with an advanced polishing surface treatment, ensures both corrosion resistance and a refined visual appeal. These features make our components ideal for sectors where aesthetics and protection are critical.

FAQs of Progressive Sheet Metal Component:

Q: How are progressive sheet metal components manufactured using MIG welding?

A: Progressive sheet metal components are produced by joining stainless steel sheets with MIG welding, an efficient process for creating strong, precise welds. This technique is particularly effective for materials with thicknesses between 1 and 10 millimeters.Q: What materials and thickness options are available for these components?

A: We utilize high-quality stainless steel with thicknesses ranging from 1 to 10 millimeters, allowing for flexibility in application and ensuring resilience under various loads.Q: When is the best time to use these sheet metal components in industrial applications?

A: Our components are best employed when durability, corrosion resistance, and reliable performance are required, especially in manufacturing, infrastructure, and equipment fabrication projects.Q: Where are your sheet metal components exported and supplied from?

A: All our progressive sheet metal components are manufactured, supplied, and exported from India, catering to both domestic and international markets.Q: What is involved in the polishing surface treatment process?

A: The polishing process involves mechanically refining the stainless steel surface to achieve a smooth, shiny finish that enhances corrosion resistance and provides a professional appearance.Q: How does the stated production capacity benefit customers?

A: With a manufacturing capacity of 10 to 50 kg/hr, we can efficiently fulfill both large and small orders, ensuring timely delivery and consistent quality for our clients.Q: What are the advantages of using progressive sheet metal components in construction and manufacturing?

A: These components offer robust strength, enhanced longevity due to stainless steel construction, and a polished finish, making them suited for high-performance and aesthetically demanding applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Parts Category

Stamped Sheet Metal Parts

Price 040 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other

Material : Other, Mild Steel, Stainless Steel, Aluminium

Surface Treatment : Other, Zinc Plated, Powder Coated, Painted, Galvanized

Usage : Automobile, Electronics, Consumer Durables, Industrial Machinery

Custom Sheet Metal Parts

Price 0.36 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other, CNC Punching, Bending, Welding

Material : Stainless Steel

Surface Treatment : Polishing

Usage : Mechanical and electrical enclosures

Sheet Metal Parts Manufacturer

Price 0.90 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other

Material : Stainless Steel

Surface Treatment : Other, Galvanized, Powder Coated

Usage : Industrial machinery, Electrical enclosures

Brass Pressed Component

Price 1.44 INR / Piece

Minimum Order Quantity : 10 Pieces, Piece

Making Process : Other

Material : Other

Surface Treatment : Polishing

Usage : ELECTRICAL

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry