- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Fly Press Parts

- Sheet Metal Dies

- Sheet Metal Components

- Shop Press Parts

- Press Tool Component

- Brass Pressed Components

- Sheet Metal Pressed Components

- Stamping Automotive Parts

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Auto Electrical Sheet Metal Components

- Custom Sheet Press part

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

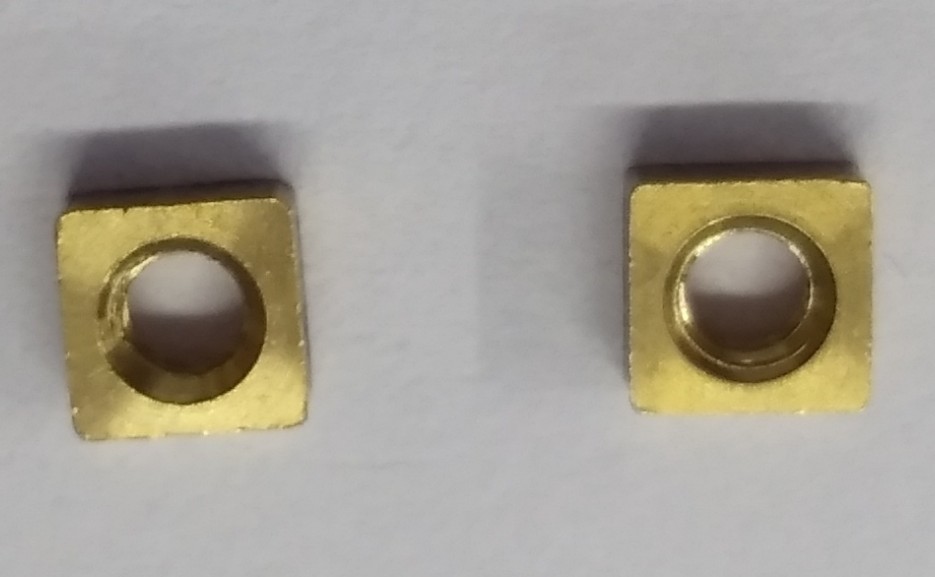

Progressive Die Components

Price 2.30 INR/ Piece

MOQ : 50 Packs

Progressive Die Components Specification

- Shape

- Rectangular, Square, Custom

- Coating Type

- Nickel Plated, Titanium Coating, Oxidized

- Components

- Punches, Die Plates, Stripper Plates, Guide Posts, Bushes, Springs, Cams

- Mount Type

- Bolted, Dowelled

- Application

- Automotive, Electrical, Electronic, Appliance, Hardware

- Weight

- Depends on design and size

- Hole Size

- Precision as per drawing

- Usage

- Stamping, Punching, Forming

- Dimension (L*W*H)

- Customizable as per drawing

- Surface Finishing

- Polished, Ground, Coated

- Material

- High Speed Steel, Tool Steel, Carbide, D2 Steel

- Tolerance

- 0.01 mm

- Thickness

- As per requirement / design

- Capacity

- Upto 100 tons (varies by design)

- Surface Treatment

- Heat Treatment, Grinding, Plating

- Making Process

- CNC Machining, EDM, Wirecut, Grinding

Progressive Die Components Trade Information

- Minimum Order Quantity

- 50 Packs

- Supply Ability

- 1000000 Packs Per Month

- Delivery Time

- 6 Days

About Progressive Die Components

Capitalise on the celebrated precision and wondrous durability of our Progressive Die Components, designed for superior performance in demanding environments. With hardness ranging from 58-62 HRC after heat treatment and a corrosion-resistant, metallic grey finish, these components are crafted using advanced CNC machining, EDM, wirecut, and grinding. Redeem the benefit of fully customisable dimensions and mounting, compatible with most press machines. OEM/ODM services are available, ensuring you receive bespoke solutions efficiently packed and handed over in secure wooden or carton boxes-all while meeting global standards and accommodating high-tonnage requirements.

Site of Application & Versatile Surface Uses

Progressive Die Components are expertly engineered for stamping, punching, and forming tasks across various industries including automotive, electrical, electronics, appliance, and hardware. Their superior application surface is enhanced with polished, ground, and coated finishes, ensuring longevity. These components seamlessly integrate at manufacturing sites, assembly lines, and fabrication workshops, providing optimal performance wherever complex metal forming is required, making them a celebrated choice for numerous industrial applications.

Payment Terms, Supply Ability & Order Processing

Order processing for our Progressive Die Components is efficient and reliable, ensuring your requirements are swiftly met. With flexible payment terms available, you can capitalise on our supply ability to fulfill both standard and custom orders without delay. Samples can be provided upon request, allowing you to assess quality before full-scale production. Each order is securely packed and handed over via robust wooden or carton boxes, guaranteeing safe delivery and complete customer satisfaction.

Site of Application & Versatile Surface Uses

Progressive Die Components are expertly engineered for stamping, punching, and forming tasks across various industries including automotive, electrical, electronics, appliance, and hardware. Their superior application surface is enhanced with polished, ground, and coated finishes, ensuring longevity. These components seamlessly integrate at manufacturing sites, assembly lines, and fabrication workshops, providing optimal performance wherever complex metal forming is required, making them a celebrated choice for numerous industrial applications.

Payment Terms, Supply Ability & Order Processing

Order processing for our Progressive Die Components is efficient and reliable, ensuring your requirements are swiftly met. With flexible payment terms available, you can capitalise on our supply ability to fulfill both standard and custom orders without delay. Samples can be provided upon request, allowing you to assess quality before full-scale production. Each order is securely packed and handed over via robust wooden or carton boxes, guaranteeing safe delivery and complete customer satisfaction.

|

Progressive sheet metal parts We would like to introduce our self as an ISO 9001:2015 certified company. We have been in the market for over 16 years. Progressive sheet metal parts are our specialty. We have modern in house progressive tool making facility to produce complex tools for intricate parts. Our expert team of tool makers ensures the design and development of precise and durable tools which can mass produce with utmost precision. We have wide range of press machines available to suit every component. We have press machines of capacity 10 ton to 45 ton of high speed of 200 to 600 spm these facilities make us stand out to our competitors and provide products at competitive price. Over the years we have given uninterrupted services to our valuable customers. We also have facility of surface finishing and plating at our reliable vendors to provide the finished products to our customers. |

FAQ's of Progressive Die Components:

Q: How do I initiate an order for custom Progressive Die Components?

A: You can start by submitting your detailed requirements or drawings. Our team will review your specifications, provide a quotation, and confirm production timelines upon approval.Q: What applications benefit most from these die components?

A: These components are ideal for stamping, punching, and forming in sectors such as automotive, electronics, appliances, and hardware manufacturing, offering celebrated reliability and superior results.Q: Where are these progressive die components typically installed?

A: Designed for compatibility with most press machines, they are typically used in assembly lines, manufacturing plants, and fabrication facilities requiring precise and efficient metal part production.Q: What is the process for surface treatment and finishing?

A: Components undergo advanced polishing, grinding, and coating processes such as nickel plating or titanium coating, ensuring corrosion resistance and optimal performance over extended durations.Q: When can I expect the components to be delivered after order confirmation?

A: Lead times generally range from 2 to 4 weeks, depending on customization and order volume. We ensure timely processing and secure packaging to meet your production schedules.Q: How easy is it to service or maintain these components?

A: The components are designed for easy disassembly and reassembly, making ongoing maintenance and servicing efficient and straightforward for continued optimal performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Progressive Sheet Metal Component Category

Sheet Metal Progressive Die

Price 2.30 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other, CNC Machining, Wire Cutting, Grinding, EDM

Weight : 30500 kg (varies with size)

Hole Size : 0.5 mm and above (as per drawing)

Thickness : 0.2 mm to 6 mm

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free