- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Shop Press Parts

- Sheet Metal Dies

- Sheet Metal Pressed Components

- Precision Custom Sheet Metal

- Fly Press Parts

- Stamping Automotive Parts

- Brass Pressed Components

- Custom Sheet Metal Stamping(S.S. 301)

- Sheet Metal Components

- Press Tool Component

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Auto Electrical Sheet Metal Components

- Custom Sheet Press part

- Brass Lug

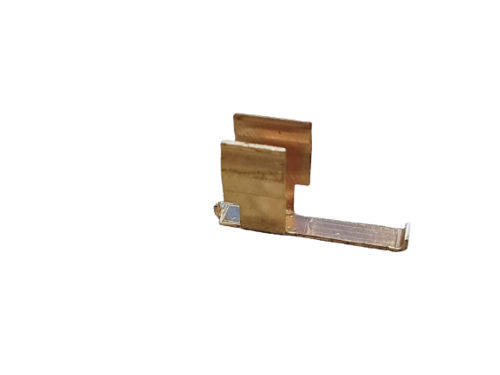

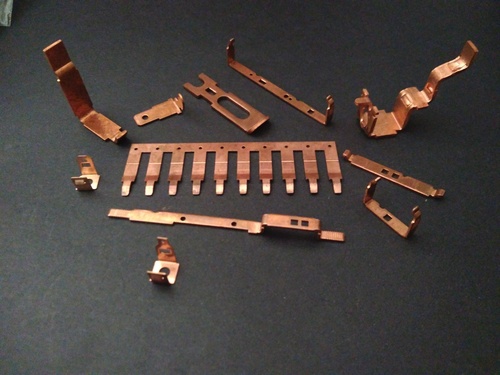

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

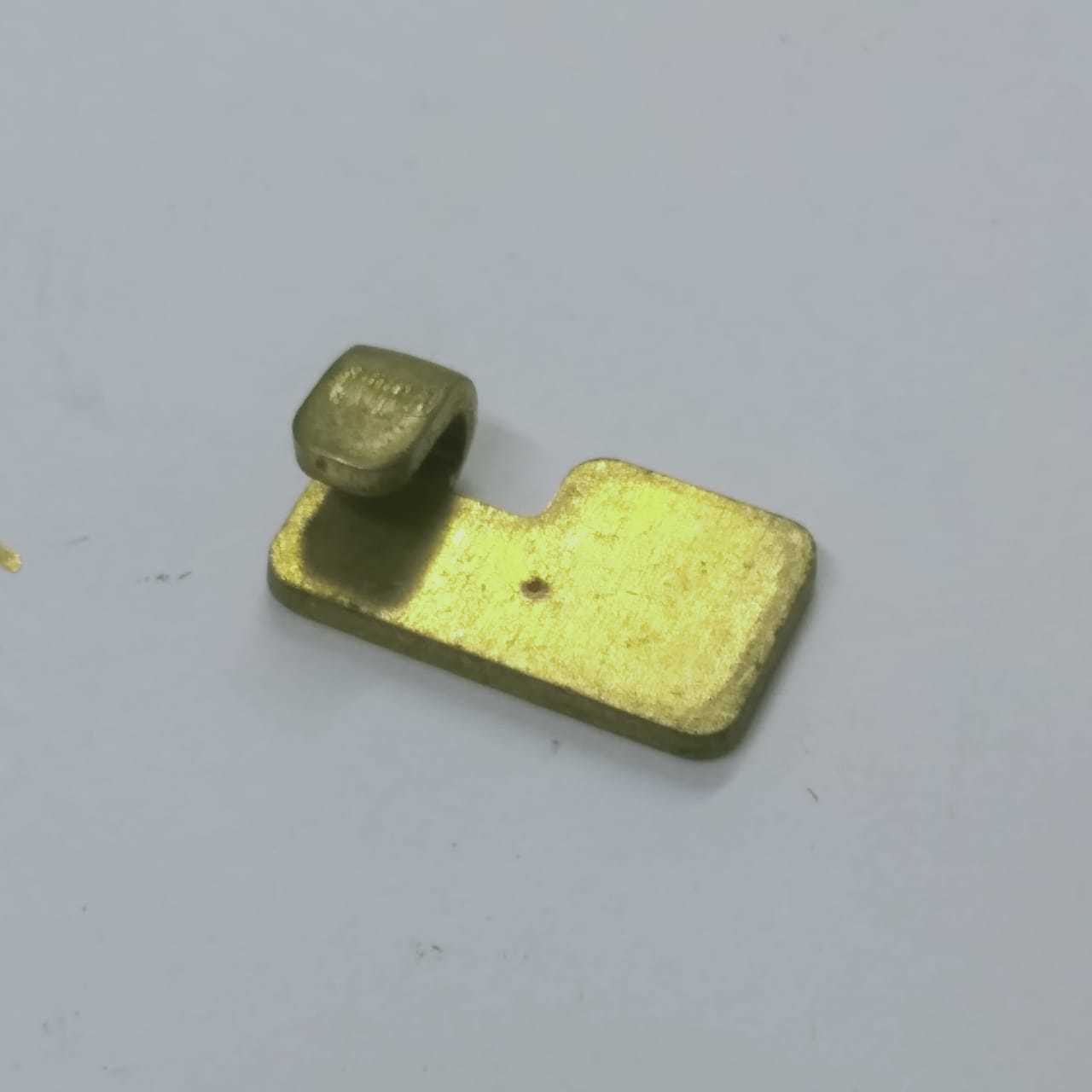

- Brass Pressed Component

- Washer Screw

- Brass Press Components

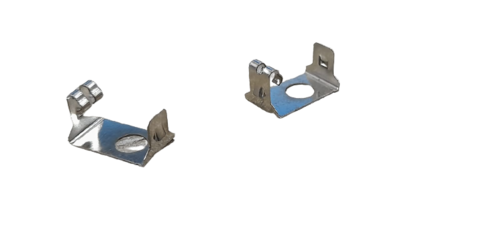

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

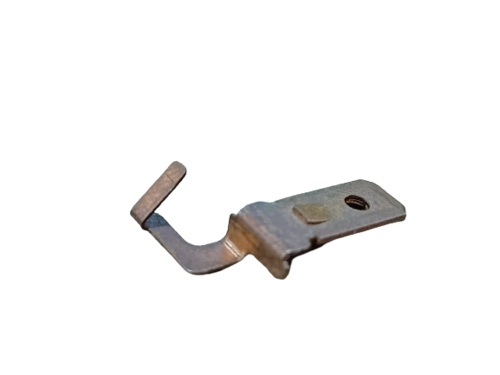

Stamped Sheet Metal Parts

Price 040 INR/ Piece

MOQ : 50000 Pieces

Stamped Sheet Metal Parts Specification

- Usage

- Automobile, Electronics, Consumer Durables, Industrial Machinery

- Coating Type

- Powder Coating, Zinc Coating

- Dimension (L*W*H)

- Custom as per drawing or requirement

- Surface Finishing

- Smooth, Matte, Glossy

- Weight

- Varies as per design

- Mount Type

- Panel Mount, Wall Mount, Surface Mount

- Application

- Mounting, Enclosures, Assembly, Electrical Fittings

- Hole Size

- Customized as per requirement

- Components

- Brackets, Clips, Covers, Supports

- Shape

- Rectangular, Square, Custom shapes

- Material

- Mild Steel, Stainless Steel, Aluminium

- Tolerance

- 0.05 mm

- Thickness

- 0.2 - 5 mm

- Capacity

- Up to 500 tons (pressing capacity)

- Surface Treatment

- Zinc Plated, Powder Coated, Painted, Galvanized

- Making Process

- Other

Stamped Sheet Metal Parts Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 1 Week

About Stamped Sheet Metal Parts

Jump on an opportunity to experience sensational quality with our stamped sheet metal partscrafted to perfection in Silver, Grey, and Black finishes. Manufactured using an exquisite blend of blanking, piercing, forming, and bending, each part boasts astonishing corrosion resistance based on surface treatment. With ISO 9001 certification and unbeatable price, you can reserve custom dimensions, smooth deburred edges, and the surface finish of your choice. Suitable for a range of materials and applications, our parts are delivered in sturdy wooden boxes or cartons within 24 weeks. Heat treatment, powder coating, and customized shapes available on request!

Primary Competitive Advantages and Application Surfaces

Our stamped sheet metal parts offer deburred edges, precise tolerances of 0.05 mm, and surfaces treated to resist corrosionmaking them ideal for mounting, enclosures, and assembly needs. Whether used in industrial machinery, consumer durables, automobiles, or electronics, these components guarantee reliability on panel, wall, or surface mount applications. Backed by a robust ISO 9001 certified process, they accommodate custom shapes, finishes, and dimensions tailored for diverse design specifications.

Delivery, Shipping, and Main Domestic Market Information

We offer competitive rates and punctual delivery, with goods shipped within 24 weeks from confirmation. All orders are securely packed in wooden boxes or cartons to prevent transit damage. Our main domestic market covers the entirety of India, with FOB port options provided for international clients. No matter the requirement, we ensure goods are delivered efficientlyso you can confidently schedule assembly or integration on your timeline.

Primary Competitive Advantages and Application Surfaces

Our stamped sheet metal parts offer deburred edges, precise tolerances of 0.05 mm, and surfaces treated to resist corrosionmaking them ideal for mounting, enclosures, and assembly needs. Whether used in industrial machinery, consumer durables, automobiles, or electronics, these components guarantee reliability on panel, wall, or surface mount applications. Backed by a robust ISO 9001 certified process, they accommodate custom shapes, finishes, and dimensions tailored for diverse design specifications.

Delivery, Shipping, and Main Domestic Market Information

We offer competitive rates and punctual delivery, with goods shipped within 24 weeks from confirmation. All orders are securely packed in wooden boxes or cartons to prevent transit damage. Our main domestic market covers the entirety of India, with FOB port options provided for international clients. No matter the requirement, we ensure goods are delivered efficientlyso you can confidently schedule assembly or integration on your timeline.

FAQs of Stamped Sheet Metal Parts:

Q: How are custom stamped sheet metal parts manufactured to meet my specifications?

A: Custom stamped sheet metal parts are produced via blanking, piercing, forming, and bending, adhering to your custom drawings and dimensional requirements. We use state-of-the-art presses and techniques, ensuring exceptional precision and finish.Q: What surface treatments and finishes are available for these parts?

A: We offer a range of surface treatments, including zinc plating, powder coating, painting, and galvanizingavailable in matte, glossy, and smooth finishes. These not only enhance appearance but also provide reliable corrosion resistance.Q: When can I expect my order to be delivered after reservation?

A: Once your order is reserved, lead times typically range from 24 weeks, depending on order complexity and customization. We prioritize timely delivery and inform you promptly of shipping details.Q: Where are these parts typically used?

A: These sheet metal parts are used for brackets, clips, covers, and supports across various applications such as mounting, enclosures, assembly, and electrical fittings in automobiles, electronics, industrial machinery, and consumer durables.Q: What are the benefits of using your stamped sheet metal parts in my project?

A: Our parts offer precision, durability, and corrosion resistance, thanks to rigorous quality controls, ISO 9001 certified processes, and high-grade materials like mild steel, stainless steel, and aluminumensuring long-lasting performance and value.Q: How does the packaging ensure the safety of shipped goods?

A: We use robust wooden boxes and cartons, providing secure packaging that protects each part from damage during transit. This ensures every component arrives in optimal condition, ready for immediate use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Parts Category

Sheet Metal Parts Manufacturer

Price 0.90 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Stainless Steel

Making Process : Other

Surface Treatment : Other, Galvanized, Powder Coated

Thickness : 0.50 Millimeter (mm)

Precision Sheet Metal Parts

Price 4.38 INR / Piece

Minimum Order Quantity : 20000 Pieces

Material : Stainless Steel, Steel, Aluminum, Copper, Other

Making Process : Stamping, Other

Automotive Sheet Metal Parts

Minimum Order Quantity : 50000 Pieces

Material : Copper, Stainless Steel, Steel, Aluminum, Other

Making Process : Other, Stamping

Surface Treatment : Nickel Plating, Other

Progressive Sheet Metal Component

Price 0.60 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Stainless Steel

Making Process : Mig Welding

Surface Treatment : Polishing

Thickness : 110 Millimeter (mm)

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free