- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Fly Press Parts

- Sheet Metal Dies

- Sheet Metal Components

- Shop Press Parts

- Press Tool Component

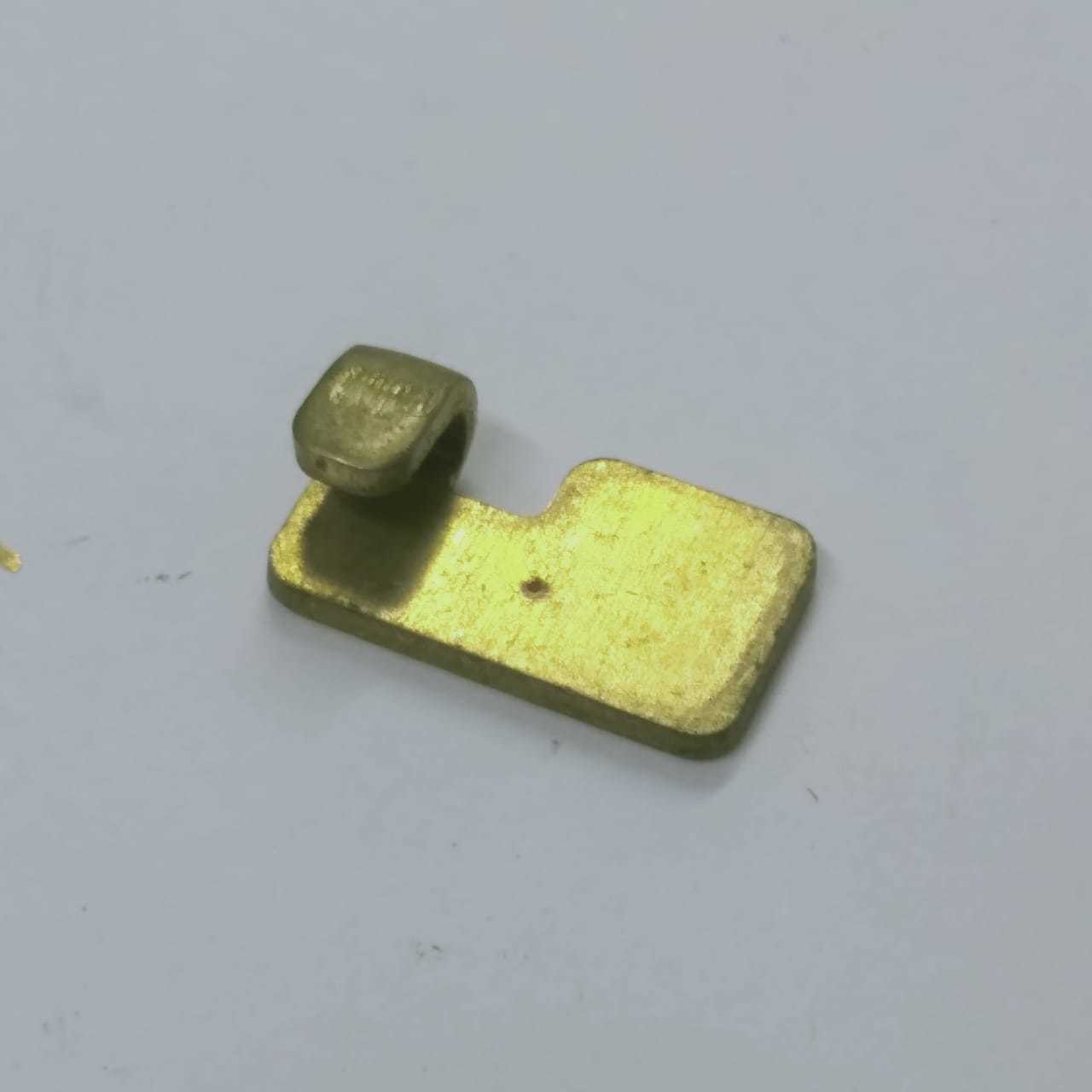

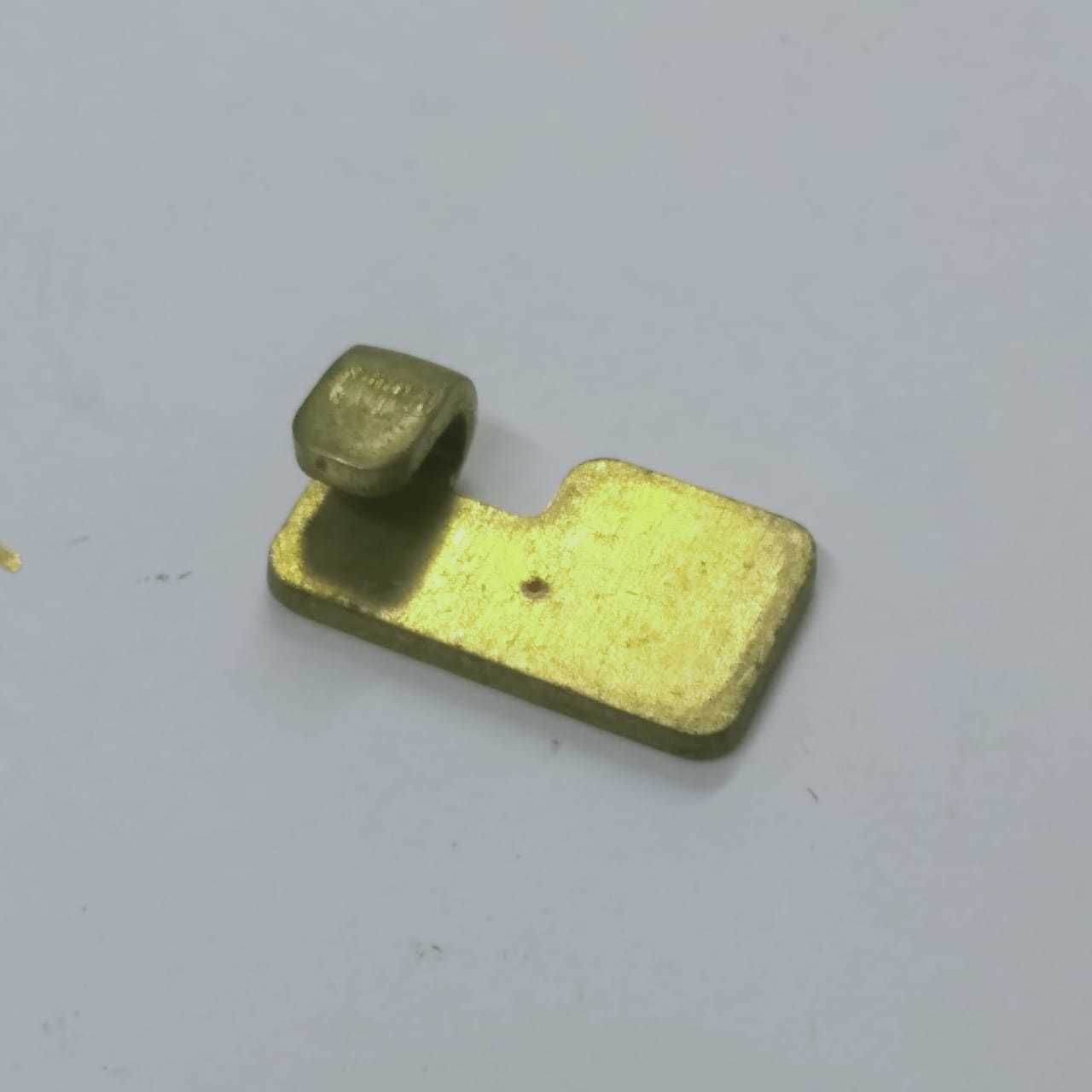

- Brass Pressed Components

- Sheet Metal Pressed Components

- Stamping Automotive Parts

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Auto Electrical Sheet Metal Components

- Custom Sheet Press part

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

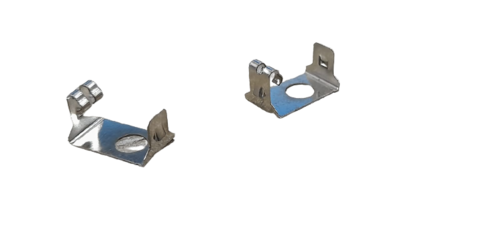

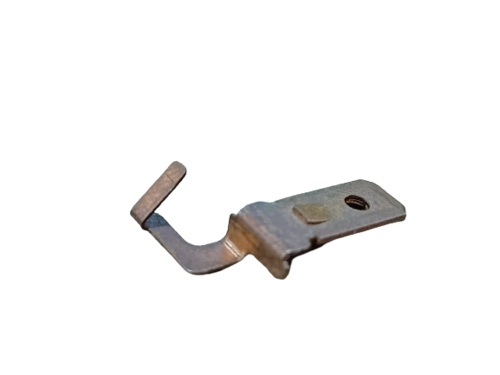

Automotive Sheet Metal Parts

MOQ : 50000 Pieces

Automotive Sheet Metal Parts Specification

- Material

- Copper, Stainless Steel, Steel, Aluminum

- Surface Treatment

- Nickel Plating

- Making Process

- Stamping

Automotive Sheet Metal Parts Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 10000000 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per industries Standers

- Main Export Market(s)

- Central America, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Africa

- Main Domestic Market

- Daman and Diu, Lakshadweep, , Himachal Pradesh, Nagaland, Uttarakhand, Dadra and Nagar Haveli, South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Jharkhand, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Central India, Odisha, West India, Chhattisgarh, All India, Haryana, Punjab, Uttar Pradesh

- Certifications

- ISO 9001-2015

About Automotive Sheet Metal Parts

SHEET METAL PARTS

Sheet metal parts manufacturing is our specialty .We are the ultimate solution provider to all your sheet metal part manufacturing requirements.

We are dealing in all types of metals including phosphor bronze, copper, EN9,EN8, EN42J, Stainless steel, Brass, mild steel within thickness range of (0.10mm to 3mm) .Having established in the year of 2005 we have many years of experience in the field of sheet metal parts manufacturing of all this materials.

We can provide sheet metal parts at a very competitive price due to our modern infrastructure and up-to-date machineries which includes imported press machines of capacity up to 45 ton of running speed 200 to 600 spm.

We are an ISO 9001:2015 certified company .We follow process approach and total employee involvement to produce best quality products.

Over the years we have manufactured various complex products in mass quantity for our esteemed customers .We have expert team of people with in-house tool manufacturing department to tackle any bottlenecks.

Advanced Stamping for Precision Parts

Our automotive sheet metal parts are manufactured using modern stamping techniques, ensuring high accuracy and consistent quality for every production run. The stamping process allows for the efficient shaping of different metals, including copper, stainless steel, steel, and aluminum, making them suitable for various automotive applications.

Nickel Plating for Enhanced Durability

To ensure long-lasting performance and exceptional resistance to wear and corrosion, our sheet metal components undergo nickel plating as a surface treatment. This process not only improves the aesthetic appeal of the parts but also provides a protective barrier, making them ideal for demanding automotive environments.

Comprehensive Global Supply Solutions

As an established exporter, manufacturer, and supplier based in India, we provide high-quality automotive sheet metal parts to clients around the globe. Our extensive experience allows us to deliver customized solutions efficiently, ensuring on-time supply and consistent support for automotive manufacturing needs.

FAQs of Automotive Sheet Metal Parts:

Q: How are automotive sheet metal parts manufactured using the stamping process?

A: Automotive sheet metal parts are created through a stamping process, where flat metal sheets are placed into a press and shaped into desired forms using dies. This method ensures precise dimensioning and the ability to produce complex shapes efficiently, suitable for high-volume automotive production.Q: What materials are commonly used for these automotive sheet metal parts?

A: Our automotive sheet metal parts are primarily manufactured using copper, stainless steel, steel, and aluminum. These materials are selected based on their strength, flexibility, conductivity, and corrosion resistance to meet the specific requirements of different automotive applications.Q: When is nickel plating applied to the automotive sheet metal parts?

A: Nickel plating is applied after the stamping process, once the parts have been formed and cleaned. This surface treatment is essential for enhancing the durability and corrosion resistance of the finished components, especially in harsh automotive environments.Q: Where are your automotive sheet metal parts supplied and exported?

A: We supply and export our automotive sheet metal parts globally, with a strong focus on serving leading automotive manufacturers and suppliers in North America, Europe, Asia, and other international markets, all from our manufacturing base in India.Q: What is the main purpose of using nickel plating on automotive sheet metal parts?

A: The primary benefit of nickel plating is to provide a strong, corrosion-resistant surface that protects the underlying metal. This extends the lifespan of the parts and makes them more reliable for use in automotive systems exposed to moisture, chemicals, and varying temperatures.Q: How can automotive manufacturers benefit from your stamped and plated sheet metal parts?

A: Automotive manufacturers benefit from our products through enhanced component reliability, extended lifespan due to corrosion resistance, cost-efficient mass production, and the flexibility to order custom-designed parts according to their exact specifications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Parts Category

Automobile Sheet Metal Parts

Price 0.30 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other

Material : Other, Mild Steel / Stainless Steel / Aluminum Alloy

Surface Treatment : Polishing

Thickness : 0.5 mm to 4 mm

Sheet Metal Parts Manufacturer

Price 0.90 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other

Material : Stainless Steel

Surface Treatment : Other, Galvanized, Powder Coated

Thickness : 0.50 Millimeter (mm)

Custom Sheet Metal Parts

Price 0.36 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other, CNC Punching, Bending, Welding

Material : Stainless Steel

Surface Treatment : Polishing

Thickness : 0.5 Millimeter (mm)

Precision Sheet Metal Parts

Price 4.38 INR / Piece

Minimum Order Quantity : 20000 Pieces

Making Process : Stamping, Other

Material : Stainless Steel, Steel, Aluminum, Copper, Other

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free