- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Sheet Metal Pressed Components

- Brass Pressed Components

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Dies

- Sheet Metal Components

- Stamping Automotive Parts

- Shop Press Parts

- Press Tool Component

- Fly Press Parts

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Custom Sheet Press part

- Auto Electrical Sheet Metal Components

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

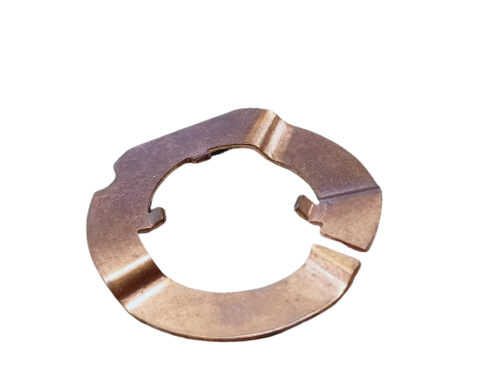

Auto Stamping Parts

Price 0.30 INR/ Piece

MOQ : 50000 Pieces

Auto Stamping Parts Specification

- Components

- Brackets, Fixings, Connectors

- Weight

- As per part specification

- Hole Size

- As per drawing requirement

- Application

- Automobile Industry

- Coating Type

- Zinc / Nickel Plating (if specified)

- Surface Finishing

- Smooth, Polished

- Usage

- Automotive Assembly

- Mount Type

- Bolt-on / Screw-on

- Dimension (L*W*H)

- As per design/drawing

- Shape

- Rectangular / Custom

- Material

- Steel / Stainless Steel / Mild Steel

- Tolerance

- 0.01 mm

- Thickness

- 0.5 mm to 5 mm

- Capacity

- High-volume stamping

- Surface Treatment

- Polishing

- Making Process

- Stamping, Punching, Cutting

- Packaging Type

- Box / Bulk

- Hardness

- 30-60 HRC

- OEM Service

- Available

- Lead Time

- 2-5 weeks

- Drawing Acceptance

- CAD, PDF, DWG

- Production Method

- Progressive Die Stamping

- Edge Type

- Deburred

- Temperature Resistance

- Up to 300°C

- Additional Product Specifications

- Corrosion Resistance

- Yes

- Color

- Metallic Silver

Auto Stamping Parts Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 1000000 Pieces Per Week

- Delivery Time

- 7 Days

About Auto Stamping Parts

Experience eminent savings and superior efficiency with our hot-selling Auto Stamping Parts, meticulously engineered for the automobile industry. Crafted from exquisite steel, stainless, or mild steel, these pivotal componentsbrackets, fixings, and connectorsare designed for high-volume stamping using progressive die techniques. Each part boasts polished, metallic silver surfaces with advanced corrosion and temperature resistance up to 300C. Our OEM service accepts CAD, PDF, and DWG drawings, ensuring deburred edges and precise tolerances of 0.01 mm. Buy from a leading exporter, manufacturer, and supplier in India for unrivaled quality and reliability.

Distinctive Features and Versatile Applications

Our Auto Stamping Parts stand out due to their smooth, deburred surfaces and exquisite polishing, making them ideal for demanding automotive assembly lines. Suited for multiple surface applications, these parts can be bolt-on or screw-on and come in rectangular or custom shapes. Widely used in brackets, fixings, and connectors, they ensure robust performance backed by zinc or nickel plating for extended corrosion resistance, making them pivotal for diverse automobile usage types.

Payment, Exchange, and Express Shipping Details

We offer flexible payment terms, ensuring minimum expenditure for clients seeking excellent savings. Products are securely packaged in boxes or bulk shipments per order requirements. With express shipping and a lead time of just 2-5 weeks, we aim to expedite your exchange processes efficiently. Our packaging details adhere to industry standards, guaranteeing product integrity and smooth transitions from our facility to your project site.

Distinctive Features and Versatile Applications

Our Auto Stamping Parts stand out due to their smooth, deburred surfaces and exquisite polishing, making them ideal for demanding automotive assembly lines. Suited for multiple surface applications, these parts can be bolt-on or screw-on and come in rectangular or custom shapes. Widely used in brackets, fixings, and connectors, they ensure robust performance backed by zinc or nickel plating for extended corrosion resistance, making them pivotal for diverse automobile usage types.

Payment, Exchange, and Express Shipping Details

We offer flexible payment terms, ensuring minimum expenditure for clients seeking excellent savings. Products are securely packaged in boxes or bulk shipments per order requirements. With express shipping and a lead time of just 2-5 weeks, we aim to expedite your exchange processes efficiently. Our packaging details adhere to industry standards, guaranteeing product integrity and smooth transitions from our facility to your project site.

FAQs of Auto Stamping Parts:

Q: How can I submit my custom design for Auto Stamping Parts?

A: We accept CAD, PDF, and DWG files for custom drawings. You can share your design along with specifications, and our OEM team will review and proceed accordingly.Q: What is the typical lead time for delivery of these parts?

A: The standard lead time for our Auto Stamping Parts ranges from 2 to 5 weeks, depending on order volume and specific customization requirements.Q: What surface treatments are available for the stamping parts?

A: Every component receives a polished finish and can be coated with zinc or nickel plating as specified in your order to enhance corrosion resistance and surface quality.Q: Where are these Auto Stamping Parts used?

A: These parts are primarily utilized in automotive assembly for brackets, fixings, and connectors, ensuring reliable performance across various automobile applications.Q: What benefits do progressive die stamping parts offer for automotive assembly?

A: Progressive die stamping enables high-volume production with consistent quality, precise tolerances, and excellent durabilityelevating overall efficiency and assembly accuracy in automotive manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stamping Parts Category

Stamping Parts

Price 1.20 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Flat/Irregular (as per design)

Tolerance : 0.02 mm

Thickness : 0.5 mm 3 mm

Surface Finishing : Smooth, Deburred

Custom Stamping Parts

Price 1.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : As per design round, square, rectangular, special shapes

Tolerance : 0.01 mm

Thickness : 0.2 mm to 8 mm

Surface Finishing : Smooth, brushed, matte, glossy

Stainless Steel Stamping Parts

Price 0.3 INR / Piece

Minimum Order Quantity : 50000 Pieces

Shape : Rectangular, Square, Circular, Customized shapes

Tolerance : 0.05 mm

Thickness : 0.5 mm to 3.0 mm

Surface Finishing : Mirror, Satin, Matt, Electroplated

Stamping Parts Manufacturer

Price 7.00 INR / Piece

Minimum Order Quantity : 50000 Pieces

Shape : Customizedrectangular, square, circular or as per design

Tolerance : 0.01 mm

Thickness : 0.2 mm to 5 mm

Surface Finishing : Smooth, Shiny, Matte, Brushed

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry