- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Sheet Metal Pressed Components

- Brass Pressed Components

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Dies

- Sheet Metal Components

- Stamping Automotive Parts

- Shop Press Parts

- Press Tool Component

- Fly Press Parts

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Custom Sheet Press part

- Auto Electrical Sheet Metal Components

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

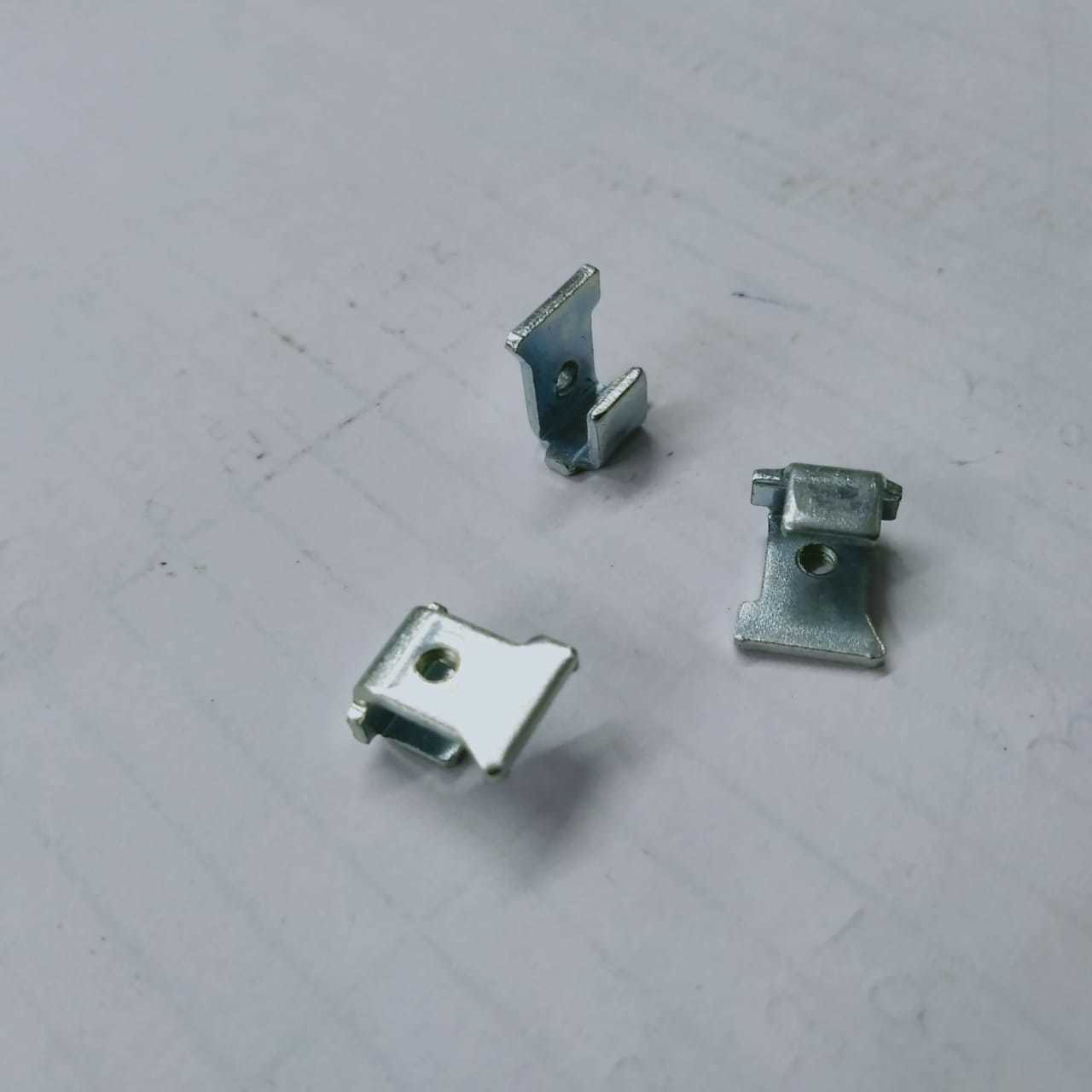

Press Die Components

Price 2.00 INR/ Piece

MOQ : 50000 Pieces

Press Die Components Specification

- Hole Size

- 1 mm to 80 mm

- Shape

- Rectangular, Square, Round, Customized

- Components

- Punch, Die, Die-set, Guide pillar, Bush, Stripper plate

- Coating Type

- TiN, TiCN, CrN, PVD/CVD

- Weight

- 2 kg to 200 kg (depending on type and size)

- Application

- Automotive, Electronics, Appliance, Industrial machinery

- Mount Type

- Bolted/Clamped

- Usage

- Sheet metal forming and stamping operations

- Dimension (L*W*H)

- Customizable as per drawing or requirement

- Surface Finishing

- Mirror finish, Fine ground

- Material

- High-speed steel, Tool steel, Tungsten carbide, Alloy steel

- Tolerance

- 0.01 mm

- Thickness

- 3 mm to 60 mm

- Capacity

- Up to 500 tons

- Surface Treatment

- Polished, Nitrided, Hard chrome, Black oxide

- Making Process

- CNC Machining, EDM, Grinding, Wire Cutting

- Hardness

- 58-62 HRC

- Interchangeability

- Available as per design

- Color

- Silver, Black, Metallic Gray

- Quality Assurance

- 100% dimensional inspection and testing

- Lead Time

- 7-21 days depending on complexity

- Heat Treatment

- Vacuum hardened, Tempered

- Service Life

- Up to 1 million cycles

- Packaging

- Wooden box or foam protected carton

- Precision Grade

- JIS Class 0/1, DIN Standard

- Operating Temperature

- Up to 400°C

Press Die Components Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 7 Days

About Press Die Components

Buy redoubtable Press Die Components that deliver ultimate performance and remarkable value. Favored with favorable reviews from top industries, these components boast a polished finish and are engineered for up to 1 million cycles. With interchangeable designs, precision grade (JIS Class 0/1 & DIN Standard), and a robust hardness of 58-62 HRC, each unit is vacuum hardened and tempered. Choose from silver, black, or metallic gray in various shapes and weights. Secure your order with a short lead time, customized dimensions, and reliable quality assurance. Suitable for both exporters and manufacturers across India.

Versatile Application for Critical Operations

Press Die Components are highly suitable for use in automotive, electronics, appliance, and industrial machinery sectors. Their robust construction and customizable design make them ideal for sheet metal forming and stamping operations. These components function effectively on a range of surface types including mirror finish and fine ground surfaces, ensuring compatibility with all kinds of bolted or clamped mounting setups. Their diverse usage type and adaptability guarantee optimal performance across varied operational environments.

Certified Excellence and Global Reach

Our Press Die Components are rated highly and comply with international certifications, assuring top-tier quality. We offer secure shipping solutions to both domestic and global markets, including Asia, Europe, and the Middle East. Our main domestic market centers in India, while global exports extend broadly. Each product is offered with precise packaging options to protect during transit, supporting distributors and end-users with reliability and excellence throughout the supply chain.

Versatile Application for Critical Operations

Press Die Components are highly suitable for use in automotive, electronics, appliance, and industrial machinery sectors. Their robust construction and customizable design make them ideal for sheet metal forming and stamping operations. These components function effectively on a range of surface types including mirror finish and fine ground surfaces, ensuring compatibility with all kinds of bolted or clamped mounting setups. Their diverse usage type and adaptability guarantee optimal performance across varied operational environments.

Certified Excellence and Global Reach

Our Press Die Components are rated highly and comply with international certifications, assuring top-tier quality. We offer secure shipping solutions to both domestic and global markets, including Asia, Europe, and the Middle East. Our main domestic market centers in India, while global exports extend broadly. Each product is offered with precise packaging options to protect during transit, supporting distributors and end-users with reliability and excellence throughout the supply chain.

FAQ's of Press Die Components:

Q: How are the Press Die Components manufactured for high performance?

A: The components are created using advanced CNC machining, EDM, grinding, and wire cutting processes, followed by vacuum hardening and tempering to achieve a consistent hardness between 58-62 HRC.Q: What surface treatments are available for these Press Die Components?

A: Surface treatments offered include polished, nitrided, hard chrome, black oxide finishes, and specialized PVD/CVD coatings such as TiN, TiCN, and CrN, ensuring superior durability and longevity.Q: When can I expect delivery after placing an order for Press Die Components?

A: Delivery lead times range between 7 to 21 days depending on design complexity and quantity, ensuring your requirements are met swiftly and efficiently.Q: Where can these Press Die Components be applied most effectively?

A: They are best utilized in automotives, electronics, appliances, and industrial machinery for sheet metal forming and stamping operations, providing high precision and resilience.Q: What are the main benefits of using these Press Die Components?

A: Benefits include long service life (up to 1 million cycles), exceptional dimensional accuracy (0.01 mm tolerance), customizable designs, and compatibility with high-speed, tool, tungsten carbide, and alloy steels for tough industrial applications.Q: How secure is the packaging and shipping process?

A: Packaging options include robust wooden boxes and foam-protected cartons, coupled with secure shipping arrangements to ensure products arrive safely both domestically and internationally.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Components Category

SHEET METAL FORMING PARTS

Price 2 INR / Piece

Minimum Order Quantity : 50000 Pieces

Surface Treatment : Other, Zinc Plated/Polished

Thickness : 1.00 Millimeter (mm)

Making Process : Other

Material : Copper

Precise Sheet Metal Components

Price 0.50 INR / Piece

Minimum Order Quantity : 50000 Pieces

Surface Treatment : Polishing

Thickness : 15 Millimeter (mm)

Making Process : Other, CNC Machining, Laser Cutting, Stamping

Material : Steel

Sheet Metal Press Parts

Price 0.12 INR / Piece

Minimum Order Quantity : 50000 Pieces

Surface Treatment : Polishing

Thickness : 2mm

Making Process : Other, Deep Drawing, Stamping

Material : Stainless Steel

Brass Pressed Component

Price 2.82 INR / Piece

Minimum Order Quantity : 50000 Pieces, Piece

Surface Treatment : Other, Nickel Plated / Natural / Tin Plated

Thickness : 0.5 3 mm (customized options available)

Making Process : Other

Material : Other

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry