- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Fly Press Parts

- Sheet Metal Dies

- Sheet Metal Components

- Shop Press Parts

- Press Tool Component

- Brass Pressed Components

- Sheet Metal Pressed Components

- Stamping Automotive Parts

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Auto Electrical Sheet Metal Components

- Custom Sheet Press part

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

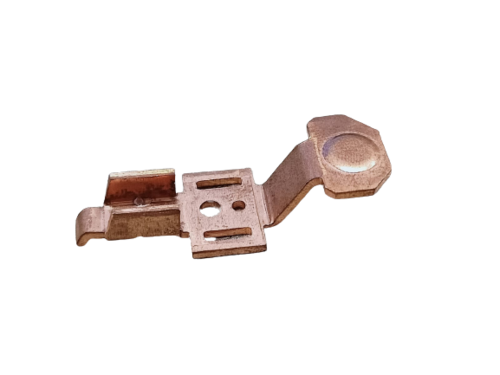

Progressive Sheet Metal Part

Price 0.25 INR/ Piece

MOQ : 50000 Pieces

Progressive Sheet Metal Part Specification

- Thickness

- 1-10 Millimeter (mm)

- Capacity

- 10-50 Kg/hr

- Surface Treatment

- Polishing

- Making Process

- Mig Welding

Progressive Sheet Metal Part Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 3-4 Week

- Main Domestic Market

- All India

About Progressive Sheet Metal Part

Progressive sheet metal parts

We would like to introduce our self as an ISO 9001:2015 certified company. We have been in the market for over 16 years. progressive sheet metal parts are our specialty.

We have modern in house progressive tool making facility to produce complex tools for intricate parts. Our expert team of tool makers ensures the design and development of precise and durable tools which can mass produce with utmost precision.

We have wide range of press machines available to suit every component. We have press machines of capacity 10 ton to 45 ton of high speed of 200 to 600 spm these facilities make us stand out to our competitors and provide products at competitive price.

Over the years we have given uninterrupted services to our valuable customers.

We also have facility of surface finishing and plating at our reliable vendors to provide the finished products to our customers.

Precision Manufacturing

Our sheet metal parts are produced using advanced MIG welding methods that guarantee strong and precise joins. The surface of each component is expertly polished to improve its resistance to corrosion and mechanical wear, ensuring an extended lifespan even in demanding environments.

Versatile Applications

Thanks to variable thickness options and robust construction, these parts serve a broad spectrum of industries, including automotive, construction, and machinery. Their capacity range supports different production scales, offering flexibility and reliability to users.

FAQs of Progressive Sheet Metal Part:

Q: How are Progressive Sheet Metal Parts manufactured?

A: These sheet metal parts are produced using the MIG welding process, which offers high-strength joints and consistency. Post welding, a polishing surface treatment is applied to achieve a smooth finish and improve durability.Q: What thickness options are available for these sheet metal parts?

A: Our Progressive Sheet Metal Parts come in variable thicknesses ranging from 1 to 10 millimeters, accommodating a wide array of requirements across different industries.Q: When is this product most beneficial for industrial use?

A: The parts are most beneficial whenever strong, corrosion-resistant components are required in production settings. Their durability and polished surface make them ideal for frequent use and exposure to harsh environments.Q: Where can these Progressive Sheet Metal Parts be utilized?

A: These components are suitable for diverse applications, including automotive assemblies, machinery fabrication, structural projects, and hardware production, both domestically and for export.Q: What is the production capacity for these sheet metal parts?

A: Our facilities produce Progressive Sheet Metal Parts at a rate of 10 to 50 Kg/hr, ensuring adequate supply for both small and large volume orders.Q: What advantages does the polishing surface treatment offer?

A: Polishing enhances the metals aesthetic appearance, improves resistance to rust and abrasions, and makes cleaning easier, thus extending the products lifespan and performance.Q: How does using MIG welding benefit the final product?

A: MIG welding provides robust and precise joins, minimizing defects and maximizing strength, thereby ensuring reliable and high-quality sheet metal parts for every project.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Progressive Sheet Metal Parts Category

Progressive Sheet Metal Parts

Price 3.30 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Other, Mild Steel / Stainless Steel / CRCA / as required

Making Process : Stamping, Other

Capacity : Customized, High Volume

Surface Treatment : Other, Zinc Plated, Powder Coated, Painted, as required

Progressive Sheet Metal Parts

Price 0.45 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Other, Stainless Steel, Mild Steel, Aluminum, Brass

Making Process : Other, Progressive Tool Stamping

Capacity : Up to 100 tons

Surface Treatment : Other, Plated, Powder Coated, Galvanized

Sheet Metal Part (Progressive)

Price 0.50 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Stainless Steel

Making Process : Mig Welding

Capacity : 1050 Kg/hr

Surface Treatment : Polishing

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free