- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Fly Press Parts

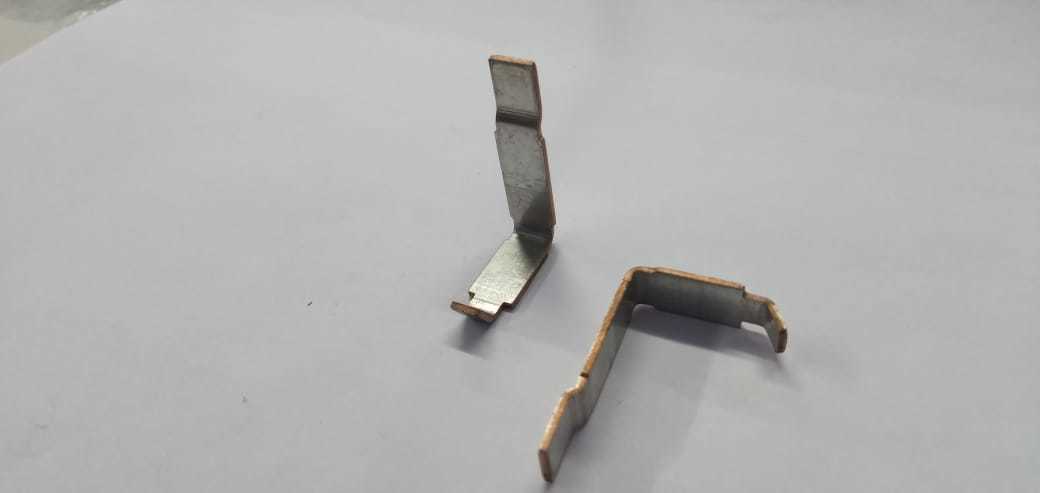

- Sheet Metal Dies

- Sheet Metal Components

- Shop Press Parts

- Press Tool Component

- Brass Pressed Components

- Sheet Metal Pressed Components

- Stamping Automotive Parts

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Auto Electrical Sheet Metal Components

- Custom Sheet Press part

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

Sheet Metal Dies

Price 2.20 INR/ Piece

MOQ : 50000 Pieces

Sheet Metal Dies Specification

- Components

- Die Block, Punch, Die Plate, Guide Pillars, Ejector Pins

- Surface Finishing

- Mirror Finish

- Hole Size

- 8 mm

- Weight

- 48 kg

- Shape

- Rectangular

- Usage

- Sheet Metal Forming

- Coating Type

- Anti-corrosive Coating

- Application

- Automotive Parts, Electrical Components Manufacturing

- Mount Type

- Adjustable Mount

- Dimension (L*W*H)

- 250 mm x 200 mm x 100 mm

- Material

- Stainless Steel

- Tolerance

- 0.02 mm

- Thickness

- 6 mm

- Capacity

- 5000 pieces/day

- Surface Treatment

- Polishing

- Making Process

- CNC Machining, EDM, Wire Cutting

Sheet Metal Dies Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 1-7 Days

About Sheet Metal Dies

Highlighted for their formidable durability and praiseworthy precision, our Sheet Metal Dies are the go-to solution for sheet metal forming. Crafted from premium stainless steel with an unprecedented hardness of 5862 HRC, these progressive dies promise an impressive life span of 1.5 million strokes. Engineered for accuracy up to 0.01 mm, each set boasts mirror finish and anti-corrosive coating, making them ideal for automotive and electrical components manufacturing. Grab the ending-soon offeravailable in metallic silver with chamfered edges, customized designs, and swift delivery in a secure wooden box.

Exceptional Application and Advantage

Sheet Metal Dies are extensively used for precision sheet metal forming across automotive and electrical component industries. Their chamfered edges and progressive die design ensure accurate alignment and high-quality output. Installed at advanced manufacturing sites, these dies offer unmatched tolerance (0.02 mm) and high stamping force for complex shapes. The advantage lies in their robust build and adaptability, making them invaluable for high-volume production and custom requirements.

Efficient Global Supply and Transport Services

Our Sheet Metal Dies are supplied from India, with goods transported via established FOB ports ensuring timely and secure delivery. Featuring a supply capacity of 5,000 pieces per day, we cater efficiently to international demands. Main export markets include Asia, Europe, and North America, supported by reliable transport services. Every shipment is managed to guarantee product integrity and rapid response times, meeting global industry needs with consistent supply and competitive logistics.

Exceptional Application and Advantage

Sheet Metal Dies are extensively used for precision sheet metal forming across automotive and electrical component industries. Their chamfered edges and progressive die design ensure accurate alignment and high-quality output. Installed at advanced manufacturing sites, these dies offer unmatched tolerance (0.02 mm) and high stamping force for complex shapes. The advantage lies in their robust build and adaptability, making them invaluable for high-volume production and custom requirements.

Efficient Global Supply and Transport Services

Our Sheet Metal Dies are supplied from India, with goods transported via established FOB ports ensuring timely and secure delivery. Featuring a supply capacity of 5,000 pieces per day, we cater efficiently to international demands. Main export markets include Asia, Europe, and North America, supported by reliable transport services. Every shipment is managed to guarantee product integrity and rapid response times, meeting global industry needs with consistent supply and competitive logistics.

FAQs of Sheet Metal Dies:

Q: How does the progressive die set improve sheet metal forming efficiency?

A: The progressive die set streamlines sheet metal forming by allowing multiple operationssuch as punching, cutting, and bendingin a single press stroke, reducing cycle times and improving consistency for high-volume production.Q: What is the process for customizing Sheet Metal Dies according to specific requirements?

A: Customization involves discussing your exact design and material needs, followed by precision CNC machining, EDM, and wire cutting processes. Our team collaborates closely to ensure each component matches your specifications before final delivery.Q: Where are these Sheet Metal Dies commonly used?

A: These dies are widely applied in automotive parts production and electrical components manufacturing, primarily at industrial sites equipped for high-accuracy stamping and forming operations.Q: When can customers expect delivery after placing an order?

A: Typically, the lead time is 3 weeks from order confirmation, which includes manufacturing, quality assurance, packaging in wooden boxes, and arranged secure transport to the specified FOB port.Q: What are the key benefits of using these dies for your manufacturing operation?

A: Clients benefit from praiseworthy wear resistance, formidable accuracy (alignment up to 0.01 mm), and unprecedented lifespan, ensuring efficient output and lower maintenance costs during long production runs.Q: How is product integrity maintained during goods transport?

A: Goods are securely packaged in wooden boxes with anti-corrosive coatings and handled by reliable transport services, ensuring safe and undamaged delivery to global export markets.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Components Category

Pressed Component

Price 0.85 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Steel

Making Process : Mig Welding

Surface Treatment : Other, Zinc Plated / Powder Coated

Thickness : 110 Millimeter (mm)

Pressed Component Ms

Price 0.50 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Stainless Steel

Making Process : Mig Welding

Surface Treatment : Other, Galvanized / Zinc Plated / Powder Coated

Thickness : 110 Millimeter (mm)

Square Washer -Brass

Price 0.30 INR / Piece

Minimum Order Quantity : 100000 Pieces, Piece

Material : Brass

Surface Treatment : Polishing

Fly Press Parts

Price 1.50 INR / Piece

Minimum Order Quantity : 50000 Pieces

Material : Other, High Grade Steel / Cast Iron

Making Process : Other, Forged and Machined

Surface Treatment : Polishing

Thickness : 1.50 Millimeter (mm)

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry