- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Sheet Metal Pressed Components

- Brass Pressed Components

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Dies

- Sheet Metal Components

- Stamping Automotive Parts

- Shop Press Parts

- Press Tool Component

- Fly Press Parts

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Custom Sheet Press part

- Auto Electrical Sheet Metal Components

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

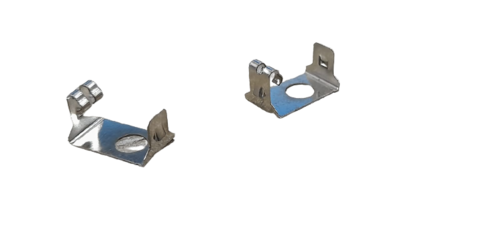

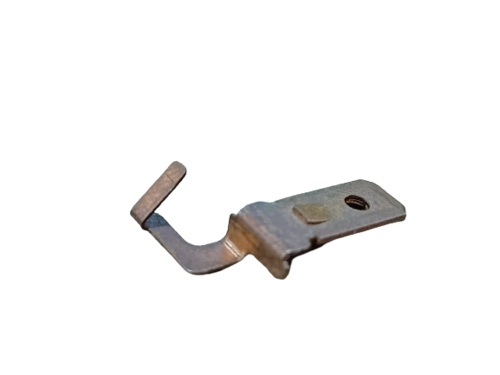

Automobile Sheet Metal Parts

Price 0.30 INR/ Piece

MOQ : 50000 Pieces

Automobile Sheet Metal Parts Specification

- Coating Type

- Zinc Coated / Powder Coated

- Dimension (L*W*H)

- Customized

- Components

- Brackets, Panels, Mounts, Reinforcements

- Shape

- Custom profile (as per design)

- Surface Finishing

- Smooth, Glossy

- Usage

- Automotive Frame and Body Part

- Weight

- Varies per design (Typically 200g 10kg)

- Hole Size

- 4 mm standard (customizable)

- Application

- Automobile Industry

- Mount Type

- Welded / Bolted

- Material

- Mild Steel / Stainless Steel / Aluminum Alloy

- Tolerance

- 0.05 mm

- Thickness

- 0.5 mm to 4 mm

- Capacity

- As per client requirement

- Surface Treatment

- Polishing

- Making Process

- Other

- Minimum Order Quantity

- 100 Pieces

- Heat Resistance

- Up to 150C

- Design Standard

- DIN / ASTM / JIS

- Corrosion Resistance

- Yes

- Color

- Metallic Silver / Custom

- Edge Type

- Deburred

- Cutting Precision

- Laser / Die Cutting

- Test Report

- Available Upon Request

- Packaging Type

- Protective Wrap / Box

- Hardness

- HRB 60-80

- OEM Support

- Available

- Part No.

- Custom Part Number Provided

- Lead Time

- 24 Weeks

- Production Technique

- CNC Stamping / Hydraulic Press Forming

Automobile Sheet Metal Parts Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 10000000 Pieces Per Month

- Delivery Time

- 1 Week

About Automobile Sheet Metal Parts

Sizzling with quality, our acclaimed Automobile Sheet Metal Parts are engineered for the finest fit and performance in automotive applications. Customizable in metallic silver or a spectrum of finishes, each part boasts stellar corrosion and heat resistance up to 150C. Employing CNC stamping and hydraulic press forming, paired with laser or die cutting, ensures astounding dimensional tolerances (0.05 mm) and precision. Available in mild steel, stainless steel, or aluminum alloy, these componentsbrackets, panels, mountsarrive polished, deburred, and zinc or powder coated for smooth, glossy, stellar durability. OEM support, customized profiles, and rapid lead times make us the destination for world-class sheet metal fabrication.

Automobile Sheet Metal Parts: Usage, Applications & Special Features

Our automobile sheet metal parts are widely used for automotive frames, body parts, and critical structure reinforcements. With a broad spectrum of applications, these components offer a combination of customizable design, outstanding hardness (HRB 6080), and smooth, glossy finishes. Special features include stellar heat and corrosion resistance, precise tolerances, and certified production standards. Each part is designed for both bolted and welded mounting, ensuring robust integration into modern vehicles. Protective packaging further ensures damage-free delivery.

FOB Port, Certifications, & Main Export Markets for Sheet Metal Parts

Automobile sheet metal parts are exported through major Indian domestic maritime FOB ports, ensuring efficient global outlay and competitive freight rates. Each batch is backed with test reports and certifications like DIN, ASTM, and JIS for guaranteed quality. Our main export markets span the USA, Europe, the Middle East, and Southeast Asia. Trusted by automotive manufacturers worldwide, our supply chain is structured for fast, reliable international deliveries with strict compliance to export standards.

Automobile Sheet Metal Parts: Usage, Applications & Special Features

Our automobile sheet metal parts are widely used for automotive frames, body parts, and critical structure reinforcements. With a broad spectrum of applications, these components offer a combination of customizable design, outstanding hardness (HRB 6080), and smooth, glossy finishes. Special features include stellar heat and corrosion resistance, precise tolerances, and certified production standards. Each part is designed for both bolted and welded mounting, ensuring robust integration into modern vehicles. Protective packaging further ensures damage-free delivery.

FOB Port, Certifications, & Main Export Markets for Sheet Metal Parts

Automobile sheet metal parts are exported through major Indian domestic maritime FOB ports, ensuring efficient global outlay and competitive freight rates. Each batch is backed with test reports and certifications like DIN, ASTM, and JIS for guaranteed quality. Our main export markets span the USA, Europe, the Middle East, and Southeast Asia. Trusted by automotive manufacturers worldwide, our supply chain is structured for fast, reliable international deliveries with strict compliance to export standards.

FAQs of Automobile Sheet Metal Parts:

Q: How are your automobile sheet metal parts customized to client specifications?

A: We offer complete customization in dimensions, thickness, hole sizes, materials, surface finishes, and coatings. Clients provide part numbers, design profiles, and requirements, and we use advanced CNC stamping and hydraulic press forming to meet precise specifications.Q: What production processes ensure the precision and quality of these parts?

A: We utilize CNC stamping, hydraulic press forming, and high-precision laser or die cutting. Deburred edges, polished surfaces, and rigorous standards (DIN/ASTM/JIS) ensure exemplary quality and consistent tolerances up to 0.05 mm.Q: When can customers expect delivery after placing an order?

A: Standard lead time is 24 weeks after finalization of design and order confirmation. Our capacity and production scheduling ensure timely completion, even for high-volume or custom projects.Q: Where can these sheet metal parts be used in the automobile industry?

A: They serve as brackets, panels, mounts, and reinforcements for automotive frames and body partssuitable for both new vehicle production and aftermarket repairs in commercial and passenger vehicles.Q: What are the benefits of your sheet metal parts for automotive manufacturers?

A: Manufacturers benefit from customizable, durable, corrosion-resistant parts that meet international standards and rigorous automotive requirements. With OEM support, precise tolerances, and smooth surface finishes, our products ensure optimal performance and seamless assembly.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Parts Category

Sheet Metal Parts Manufacturer

Price 0.90 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other

Thickness : 0.50 Millimeter (mm)

Surface Treatment : Other, Galvanized, Powder Coated

Material : Stainless Steel

Custom Sheet Metal Parts

Price 0.36 INR / Piece

Minimum Order Quantity : 50000 Pieces

Making Process : Other, CNC Punching, Bending, Welding

Thickness : 0.5 Millimeter (mm)

Surface Treatment : Polishing

Material : Stainless Steel

Precision Sheet Metal Parts

Price 4.38 INR / Piece

Minimum Order Quantity : 20000 Pieces

Making Process : Stamping, Other

Material : Stainless Steel, Steel, Aluminum, Copper, Other

Brass Pressed Component

Price 1.44 INR / Piece

Minimum Order Quantity : 10 Pieces, Piece

Making Process : Other

Thickness : 1 Millimeter (mm)

Surface Treatment : Polishing

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry