- Home Page

- Company Profile

-

Our Products

- Sheet Metal Components

- Sheet Metal Pressed Components

- Brass Pressed Components

- Custom Sheet Metal Stamping(S.S. 301)

- Precision Custom Sheet Metal

- Sheet Metal Dies

- Sheet Metal Components

- Stamping Automotive Parts

- Shop Press Parts

- Press Tool Component

- Fly Press Parts

- Sheet Metal Components

- Automotive Sheet Metal Components

- Sheet Metal Component

- Sheet Metal Components Parts Manufacturer

- Pressed Sheet Metal Component

- Precise Sheet Metal Components

- Custom Sheet Press part

- Auto Electrical Sheet Metal Components

- Brass Lug

- Copper Pressed Parts

- Copper Pressed Components

- Pressed Component Ms

- Pressed Component

- Pressed Components

- Brass Pressed Component

- Washer Screw

- Brass Press Components

- Industrial Switchgear Terminals

- Metal Parts Stamping

- Press Die Components

- Pressed Parts

- SHEET METAL FORMING PARTS

- Press Tool Part

- Stamping Steel Parts

- Stamped Sheet Metal

- Power Press Parts

- Press Tool Components

- Stamping Metal Part

- Pressed Brass Component

- Square Washer -Brass

- Screw Assembly

- Copper Pressed Part

- Sheet Metal Press Tool

- Stamping Press Parts

- Stamping Die Parts

- Sheet Metal Press Parts

- Pressed Metal Parts

- Precision Sheet Metal Components

- Sheet Metal Parts

- Power Pressed Components

- Stamping Parts

- Punching Parts

- Progressive Sheet Metal Component

- Press Tool Parts

- Progressive Sheet Metal Parts

- Cage Nut

- Terminal Parts

- Sheet Metal Components

- Extra Links

- Contact Us

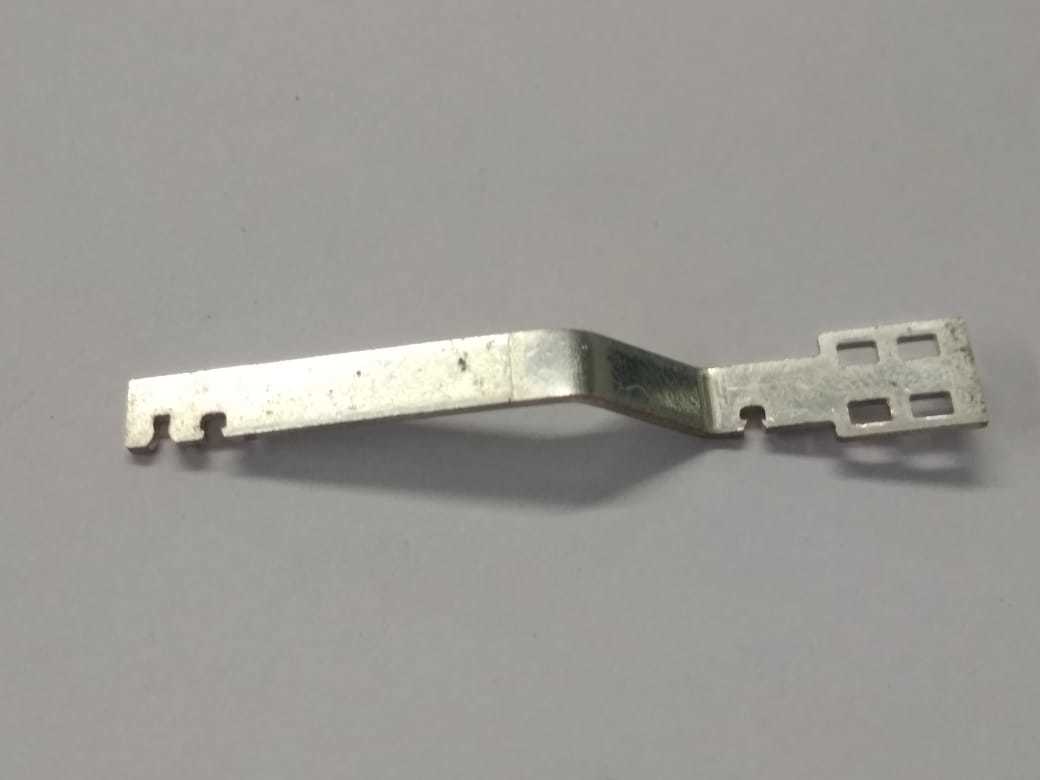

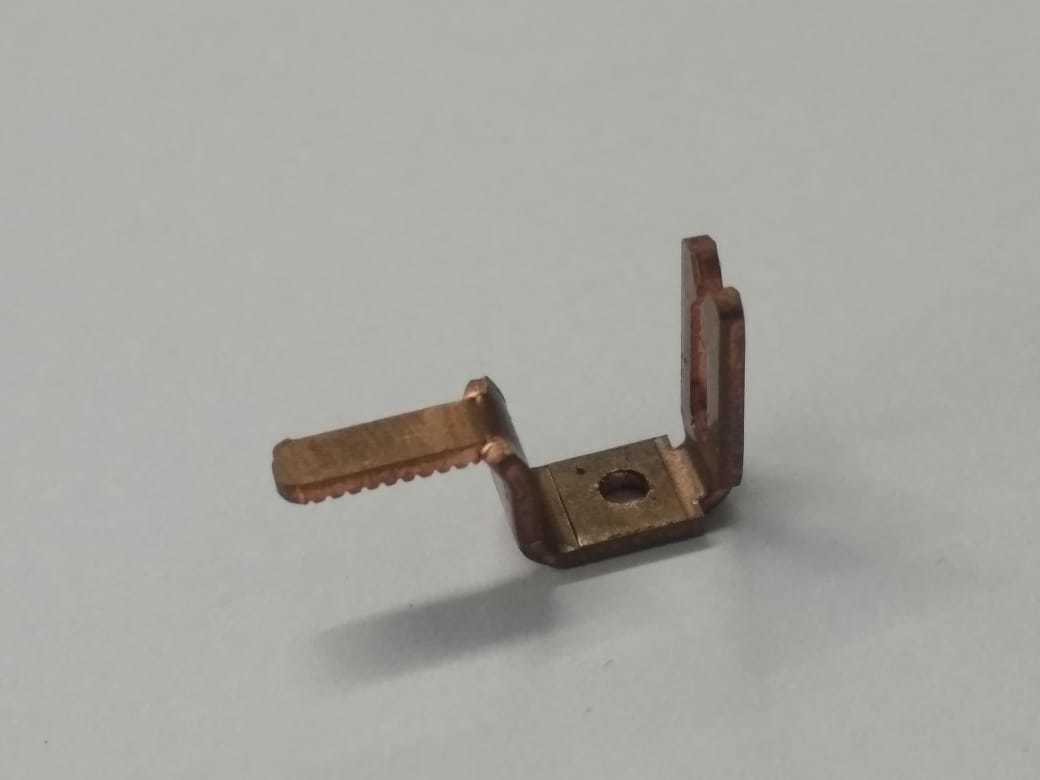

Power Press Parts

Price 0.80 INR/ Piece

MOQ : 50000 Pieces

Power Press Parts Specification

- Hole Size

- Customized as per design, ranges from 5 mm to 40 mm

- Usage

- Industrial pressing and forming operations

- Application

- Used in Power Press machines for metal sheet forming

- Mount Type

- Bolt-on / Clamp type

- Dimension (L*W*H)

- Standard / Custom as per requirement

- Coating Type

- Anti-corrosive

- Shape

- Rectangular / Custom shapes available

- Surface Finishing

- Smooth polished

- Weight

- Depends on size and application, typically 10 kg 150 kg

- Components

- Die, punch, base, stripper plate

- Material

- High grade alloy steel

- Tolerance

- 0.01 mm

- Thickness

- 5 mm 50 mm

- Capacity

- Suitable for Power Presses up to 250 Tons

- Surface Treatment

- Polishing

- Making Process

- Other

- Machining Accuracy

- CNC precision machining

- Hardness

- 52-58 HRC

- Lead Time

- 7-10 business days

- Color

- Metallic grey/black

- Corrosion Resistance

- Yes

- Heat Treatment

- Fully heat treated for durability

- Installation Type

- Ready to install

Power Press Parts Trade Information

- Minimum Order Quantity

- 50000 Pieces

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 7 Days

About Power Press Parts

Unlock the finest deals on Power Press Parts! Utilise this hot deal to equip your press machines with preeminent components renowned for potent performance. Crafted from high-grade alloy steel, these parts undergo full heat treatment and CNC precision machining, ensuring hardness of 52-58 HRC and supreme durability. Ready to install and IS/ISO certified, each part boasts smooth, polished surfaces and anti-corrosive coating. Available in standard or custom dimensions, for capacities up to 250 tons, theyre ideal for industrial pressing. Offer includes die, punch, base, and stripper plateexporter, manufacturer, and supplier from India.

Special Features and Application of Power Press Parts

Power Press Parts exhibit exceptional hardness, precision, and corrosion resistance, delivering optimal performance in demanding industrial environments. Specifically designed for metal sheet forming, these components are suitable for general and specialised usage in power presses up to 250 tons. The finely polished surfaces, bolt-on or clamp mounting, and customizable dimensions ensure smooth installation and adaptability across varied surfaces and machine settings, enhancing both productivity and reliability.

Supply Ability and Certification for Power Press Parts

Our premium supply ability guarantees prompt dispatch of orders with flexible sample availability before placing bulk requests. Every item is IS/ISO certified, reflecting adherence to international standards for safety and quality. Samples may be provided free or with a nominal charge, and typical lead time for delivery stands at 7-10 business days. We facilitate consistent, reliable exports and supply to manufacturers and suppliers across India, ensuring all products maintain high-grade certification.

Special Features and Application of Power Press Parts

Power Press Parts exhibit exceptional hardness, precision, and corrosion resistance, delivering optimal performance in demanding industrial environments. Specifically designed for metal sheet forming, these components are suitable for general and specialised usage in power presses up to 250 tons. The finely polished surfaces, bolt-on or clamp mounting, and customizable dimensions ensure smooth installation and adaptability across varied surfaces and machine settings, enhancing both productivity and reliability.

Supply Ability and Certification for Power Press Parts

Our premium supply ability guarantees prompt dispatch of orders with flexible sample availability before placing bulk requests. Every item is IS/ISO certified, reflecting adherence to international standards for safety and quality. Samples may be provided free or with a nominal charge, and typical lead time for delivery stands at 7-10 business days. We facilitate consistent, reliable exports and supply to manufacturers and suppliers across India, ensuring all products maintain high-grade certification.

FAQs of Power Press Parts:

Q: How are Power Press Parts installed on machines?

A: Power Press Parts are engineered for easy integration, using either bolt-on or clamp-type mounts. This design supports quick, hassle-free installation on power press machines.Q: What is the benefit of choosing CNC precision machined Power Press Parts?

A: CNC precision machining ensures each component adheres to tight tolerances (0.01 mm), delivering superior fit, long service life, and consistent operation in industrial applications.Q: Where are these Power Press Parts primarily used?

A: They are predominantly used in industrial pressing and forming operations, especially for metal sheet forming in power press machines with capacities up to 250 tons.Q: What is the process for ordering custom Power Press Parts?

A: Customers can specify requirements such as dimensions, shape, thickness, and hole size. After confirmation, premium-grade samples may be supplied upon request before full order dispatch.Q: When can I expect my order to be delivered?

A: Standard lead time for dispatch is 7-10 business days after order confirmation. Custom orders may require additional processing time depending on specifications.Q: How does the surface treatment benefit the application?

A: The smooth polished finish and anti-corrosive coating enhance durability, reduce wear, and maintain the integrity of parts in harsh industrial environments, thus prolonging service intervals and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Metal Components Category

Auto Electrical Sheet Metal Components

Price 0.50 INR / Piece

Minimum Order Quantity : 50000 Pieces

Surface Treatment : Polishing

Material : Other, Mild Steel / Stainless Steel

Weight : As per Design

Making Process : Mig Welding

Square Washer -Brass

Price 0.30 INR / Piece

Minimum Order Quantity : 100000 Pieces, Piece

Surface Treatment : Polishing

Material : Brass

Weight : 1 Grams (g)

Precision Custom Sheet Metal

Price 2.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Powder Coated, Galvanized, Anodized

Material : Other, Stainless Steel, Mild Steel, Aluminum

Weight : Varies as per design and material

Making Process : Other, Laser Cutting, CNC Bending, Welding, Punching

Press Die Components

Price 2.00 INR / Piece

Minimum Order Quantity : 50000 Pieces

Surface Treatment : Other, Polished, Nitrided, Hard chrome, Black oxide

Material : Other, Highspeed steel, Tool steel, Tungsten carbide, Alloy steel

Weight : 2 kg to 200 kg (depending on type and size)

Making Process : Other, CNC Machining, EDM, Grinding, Wire Cutting

We deal in bulk queries!

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free